At Bart Tangermann’s (aka De3DPrintman) Lab, based in Leiden, we turn ideas into reality with professional 3D printing services. Whether you’re a designer, entrepreneur, student, or hobbyist, we offer expeert support from concept to finished product. Discover rapid prototyping, custom designs, and innovative solutions-all under one roof. Let’s shape the future together, one layer at a time.

Welcome to De3DPrintman, your creative partner for professional 3D printing in the heart of Leiden. Whether you’re an innovator, entrepreneur, or curious maker, our lab at PLNT Leiden is the ideal place to bring your ideas to life with the latest technology and expert support. Discover what drives us, how we work, and why we’re passionate about turning your concepts into reality.

Learn more about our story and what we can do for you below.

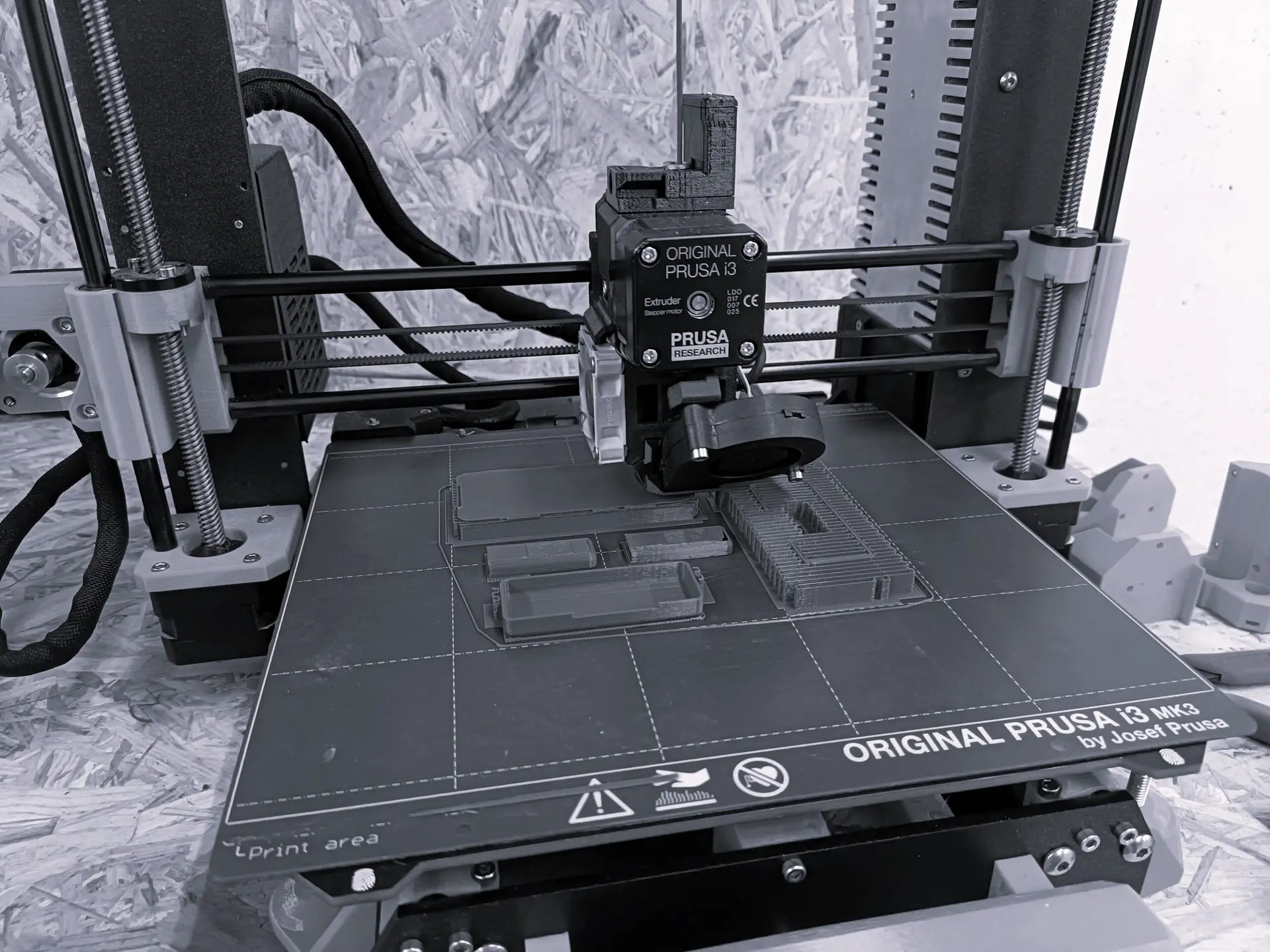

High-quality 3D printing for prototypes, parts, and models—fast, reliable, and precise.

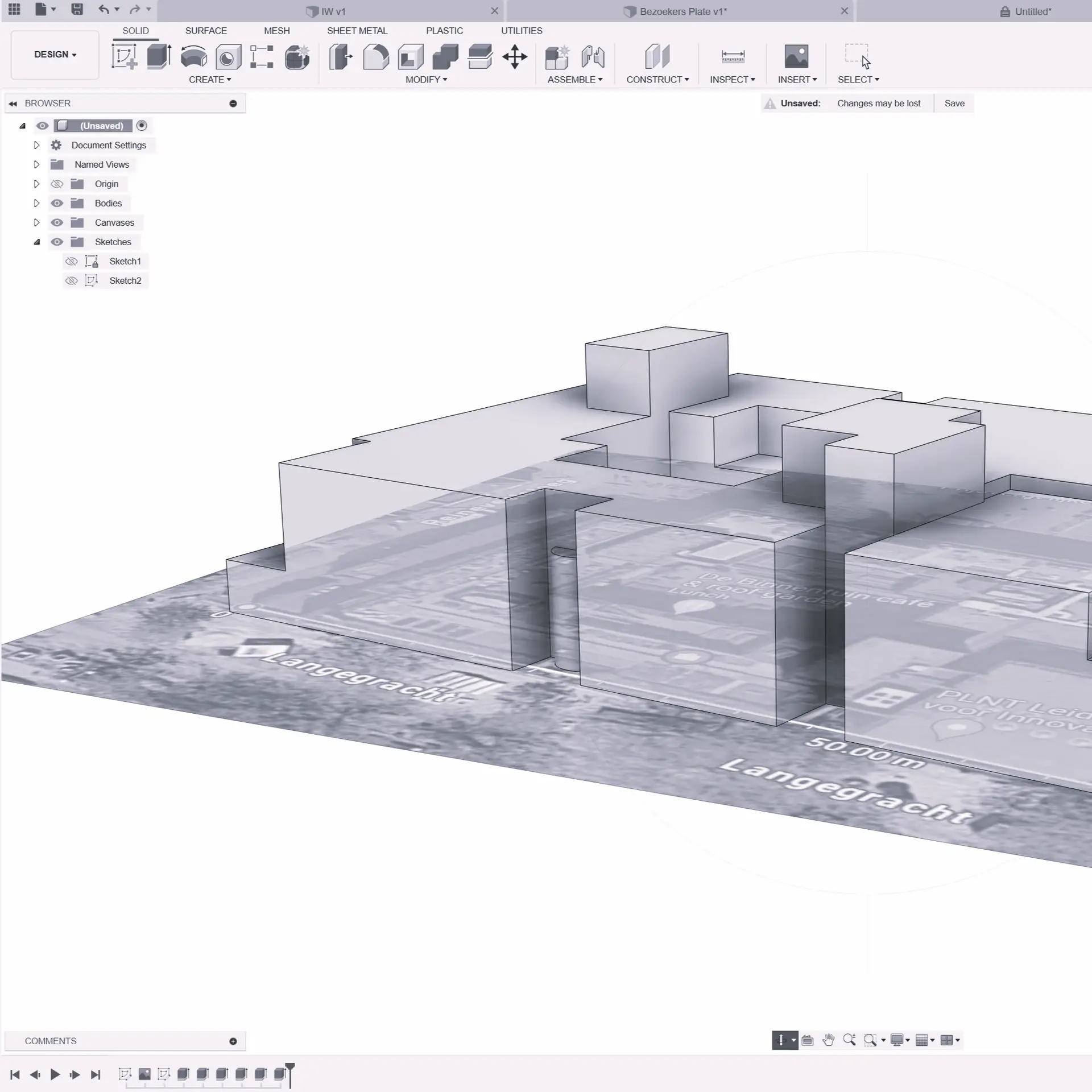

From idea to 3D model—custom design and prototyping support for every project.

Learn 3D printing with our practical workshops and expert training at PLNT Leiden.

Expert advice and innovation support for successful, cutting-edge 3D printing projects.

At De3DPrintman, you benefit from hands-on guidance and expert support at every stage of your project—plus rapid, reliable 3D printing using the latest technology. We make sure your ideas are realized quickly and exactly the way you envision them.

Get your ideas into your hands quickly. Our advanced 3D printing technology allows for rapid prototyping and quick production, so you can test, iterate, and launch your products faster than ever before.

We bring even the most complex or customized designs to life. 3D printing enables us to create intricate geometries and tailor-made solutions that traditional manufacturing simply can’t match.

Save on tooling, labor, and material costs—especially for small batches or one-off items. Our process minimizes waste and eliminates expensive setup, making high-quality production accessible and affordable.

Work directly with experienced professionals who guide you from concept to creation. We offer hands-on advice, design optimization, and dedicated support to ensure your project’s success—every step of the way.

Now is the perfect moment to take your idea to the next level. By reaching out today, you’ll get immediate access to our expert advice, the latest Prusa 3D printing technology, and the creative energy of PLNT Leiden’s innovation hub. Don’t let your innovation wait—contact De3DPrintman now and discover how quickly your concept can become reality with the best tools and support in the field. Your breakthrough starts here, powered by PLNT and Prusa!